Overview

The VIZ 1300 rotary shredder addresses the challenge of frequently changing input materials by offering an efficient and adaptable shredding machine in a compact footprint. Distinguishing features of this industrial shredder include a large shredding chamber that can process bales, tall ram for bulky material, and a contoured design for less grime accumulation. This affordable shredder has low operating costs, showing a rapid return on your investment.

Build Your Custom VIZ Shredder

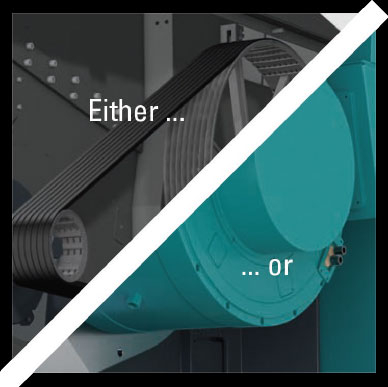

Drive Options

Either the patented ESC drive

- Cost-effective operation

- Slippage detection in real time

- Intelligent, self-regulating drive

- Low maintenance and wear

Or the HiTorc™ drive

- Synchronous motor as a direct drive without a mechanical drive train

- Highest possible torque at low speed

- Trouble-free start-up phase, even with a full hopper

- Maintenance-free and wear-free

- Remarkably quiet

Rotor Options

U Rotor

- Profiled with toothed counter knife

- Variable number of cutters from single row up to triple row of cutters depending on cutter size

W/V Rotor

- Maximum cutting performance and high throughout

- Homogeneous output quality with minimum fine dust and little particle variance

- Variable number of cutters from single row, triple row, up to fivefold (W rotor only) row of cutters depending on cutter size

- Optional bolted tool holders for more flexibility and ease of maintenance

Features

- One shredder stage versus two

- Choose from Vecoplan’s patented ESC belt drive or HiTorc™ drive

- 20" rotor diameter

- Rotor speed of 50-250 rpm

- Two rotor options include traditional single cutters or the innovative plates that hold multiple cutters, making for quick rotor change-outs

- Cutter plates available with one to three rows of cutters, depending on cutter size

- Cutter sizes available in 23x23 mm/40x40 mm/60x60 mm/80x80mm

- Large shredding chamber and improved ram height for bulky items and bales

- Hydraulic lift-up-cutter chamber floor provides the safest and most convenient access to cutting chamber

- Contoured design for better cleaning and reduced susceptibility to dirt•Swing-out, robust screen allows for simple, quick, and easy exchange

- Variable positioning of screen segments maximizes life of high-wear parts

- Pulling design of ram hydraulic unit prevents dirt and contamination, saves space and improves accessibility

- Push button ease for material changes or tramp metal removal

Brochures

(Size: 4 MB)